Blog and News

Stay up to date with Objex Unlimited and the world of 3D with our news, resources, guides, and additive manufacturing insight. Subscribe to get the latest news on 3D printing, 3D scanning, and 3D design services

Stay up to date with Objex Unlimited and the world of 3D with our news, resources, guides, and additive manufacturing insight. Subscribe to get the latest news on 3D printing, 3D scanning, and 3D design services

https://objexunlimited.com/objexunlimited/wp-content/uploads/2015/09/CMTS-smart-image1.jpg

160

240

Objex Unlimited

https://objexunlimited.com/objexunlimited/wp-content/uploads/2017/11/OBJEX_LOGO_WHITE_17-copy-300x153.png

Objex Unlimited2015-09-15 13:58:592016-01-06 16:46:26Canadian Manufacturing Technology Show (CMTS) 2015 is coming to Toronto!

https://objexunlimited.com/objexunlimited/wp-content/uploads/2015/09/CMTS-smart-image1.jpg

160

240

Objex Unlimited

https://objexunlimited.com/objexunlimited/wp-content/uploads/2017/11/OBJEX_LOGO_WHITE_17-copy-300x153.png

Objex Unlimited2015-09-15 13:58:592016-01-06 16:46:26Canadian Manufacturing Technology Show (CMTS) 2015 is coming to Toronto! https://objexunlimited.com/objexunlimited/wp-content/uploads/2015/09/ga1504-280x362.jpg

362

280

Objex Unlimited

https://objexunlimited.com/objexunlimited/wp-content/uploads/2017/11/OBJEX_LOGO_WHITE_17-copy-300x153.png

Objex Unlimited2015-09-14 11:53:172017-04-18 16:31:38Is your business ready for the 3D Printing revolution?

https://objexunlimited.com/objexunlimited/wp-content/uploads/2015/09/ga1504-280x362.jpg

362

280

Objex Unlimited

https://objexunlimited.com/objexunlimited/wp-content/uploads/2017/11/OBJEX_LOGO_WHITE_17-copy-300x153.png

Objex Unlimited2015-09-14 11:53:172017-04-18 16:31:38Is your business ready for the 3D Printing revolution? https://objexunlimited.com/objexunlimited/wp-content/uploads/2017/11/OBJEX_LOGO_WHITE_17-copy-300x153.png

0

0

Objex Unlimited

https://objexunlimited.com/objexunlimited/wp-content/uploads/2017/11/OBJEX_LOGO_WHITE_17-copy-300x153.png

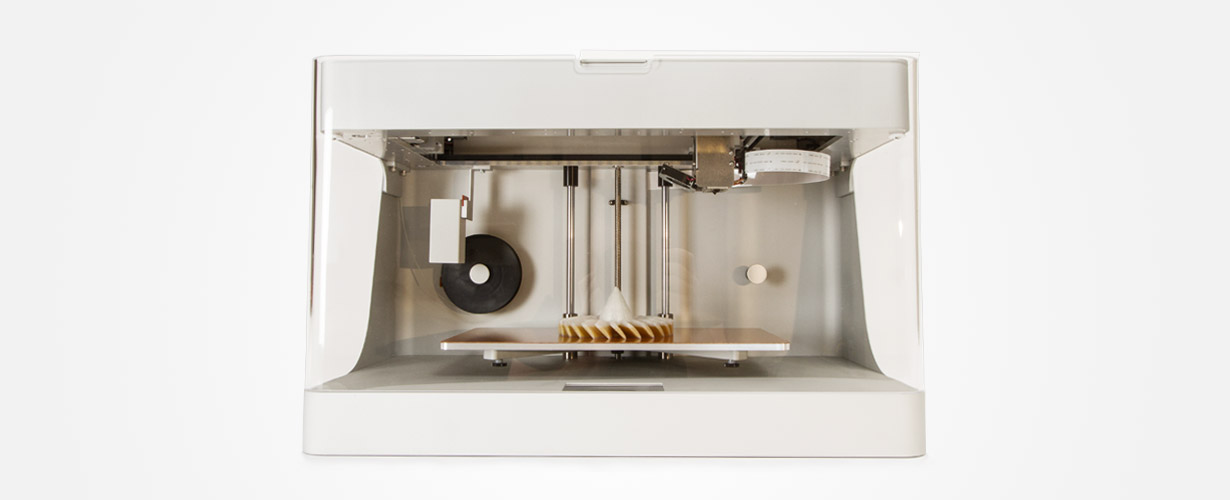

Objex Unlimited2015-08-17 11:40:592016-07-14 17:17:38What you need to know about adding 3D printing as a new revenue stream

https://objexunlimited.com/objexunlimited/wp-content/uploads/2017/11/OBJEX_LOGO_WHITE_17-copy-300x153.png

0

0

Objex Unlimited

https://objexunlimited.com/objexunlimited/wp-content/uploads/2017/11/OBJEX_LOGO_WHITE_17-copy-300x153.png

Objex Unlimited2015-08-17 11:40:592016-07-14 17:17:38What you need to know about adding 3D printing as a new revenue stream

2140 Dunwin Drive.,

Mississauga, Ontario L5L 1C0

Email: sales@objexunlimited.com

Phone: 416-233-7165

Mon – Fri

9am – 5pm EST