3D Printing in the retail space is nothing new, but we continue to see innovation in the footwear space, and how 3D Printing continues across more than just product design and development divisions.

At the forefront of the footwear industry, Adidas has been using 3D printing for years now and has even released shoes like The 4D run using cutting edge 3D printed midsoles. Nowadays brands like Reebok are utilizing advancements in full-color 3D Printing for promotional, marketing, and advertising material outside of just the product development stages.

Objex Unlimited was fortunate enough to work on this project for Reebok Canada to re-create miniature mockups of the release of The Zig for their recent viral Tik Tok campaign seen below:

The team at Reebok came to Objex Unlimited with a pair of “Zig’s”, and a concept of creating a miniature pair for their social influencers’ upcoming video campaign. They provided a few image examples and creative freedom on making it happen, and within a few weeks, we were able to deliver just that. A fresh pair of 3D Printed mini-kicks.

Here is the original Zig reference by Reebok:

The process looked something like this:

THE SHOE

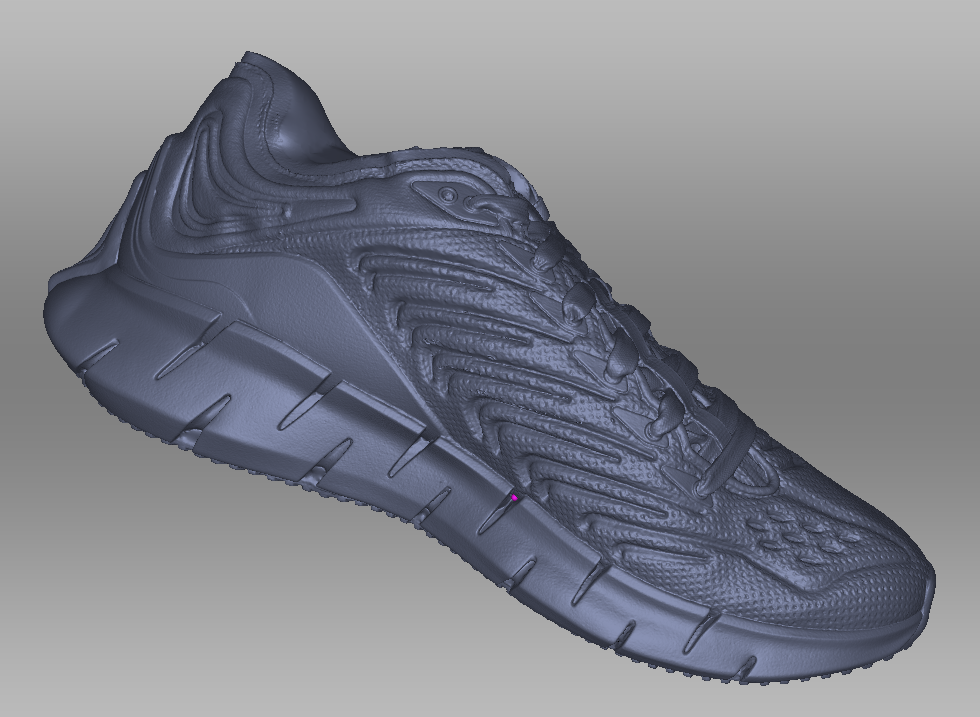

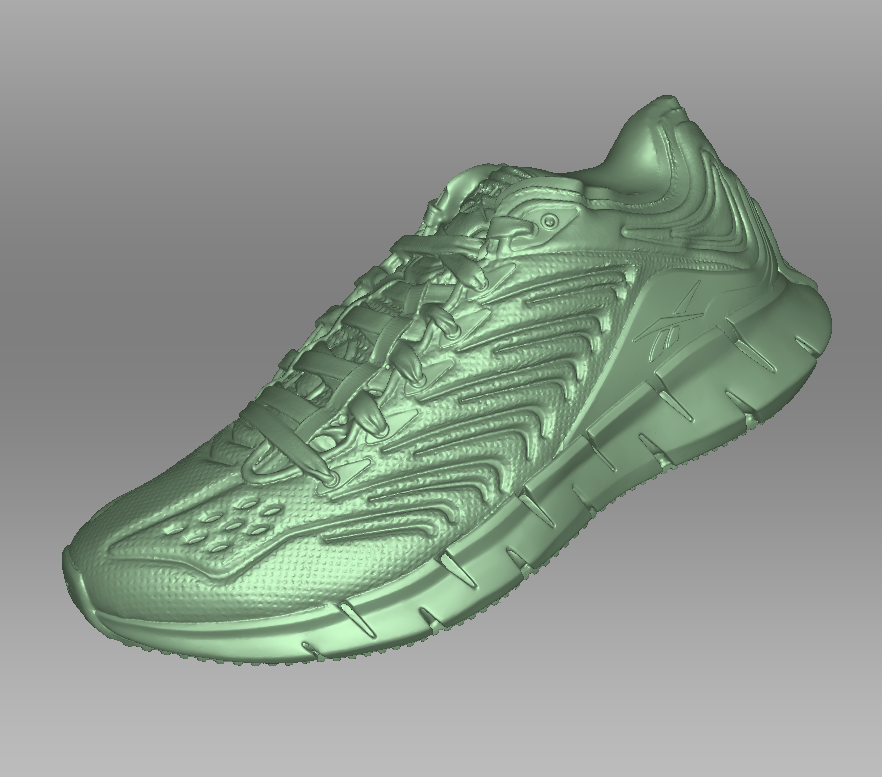

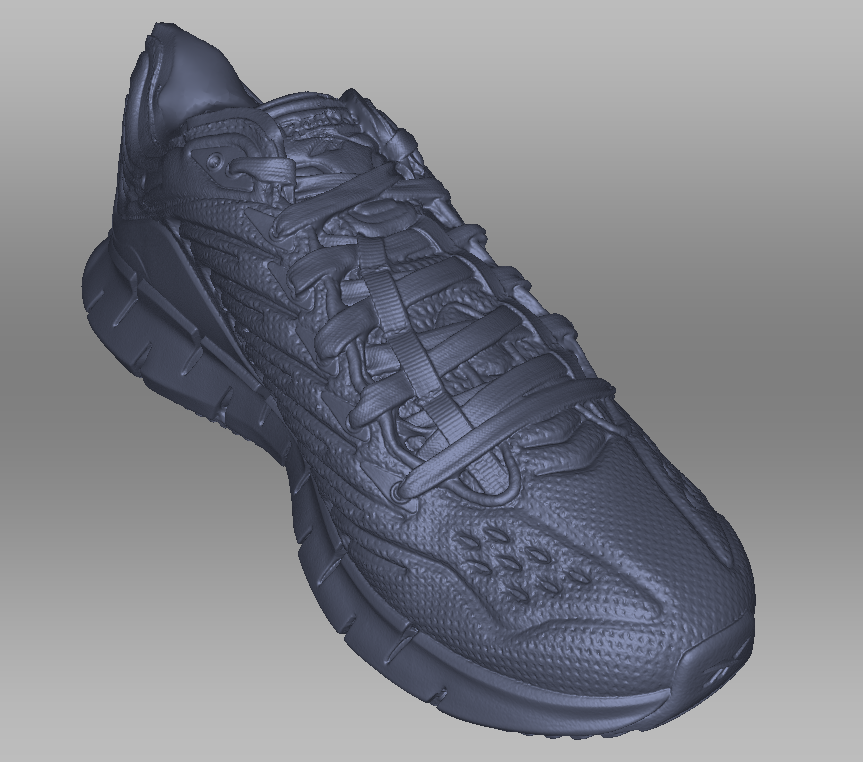

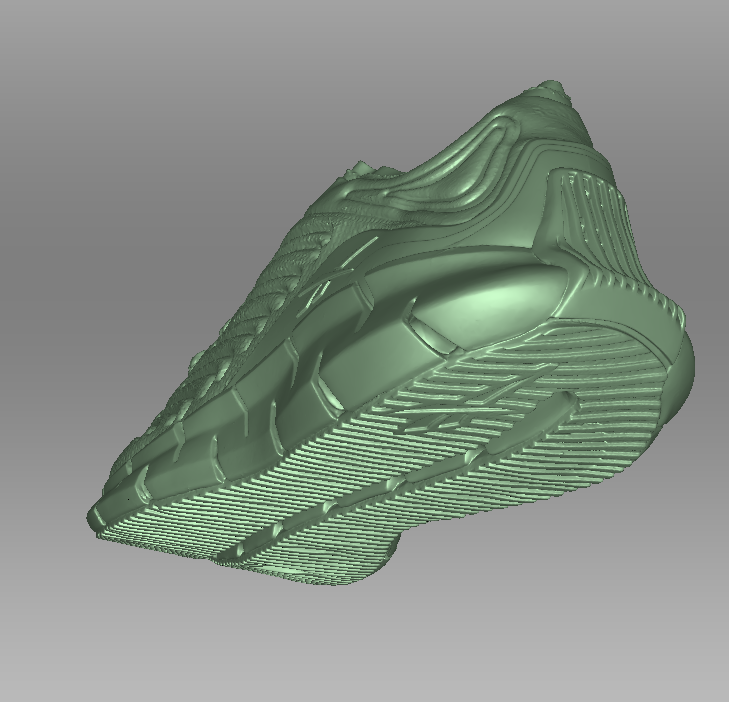

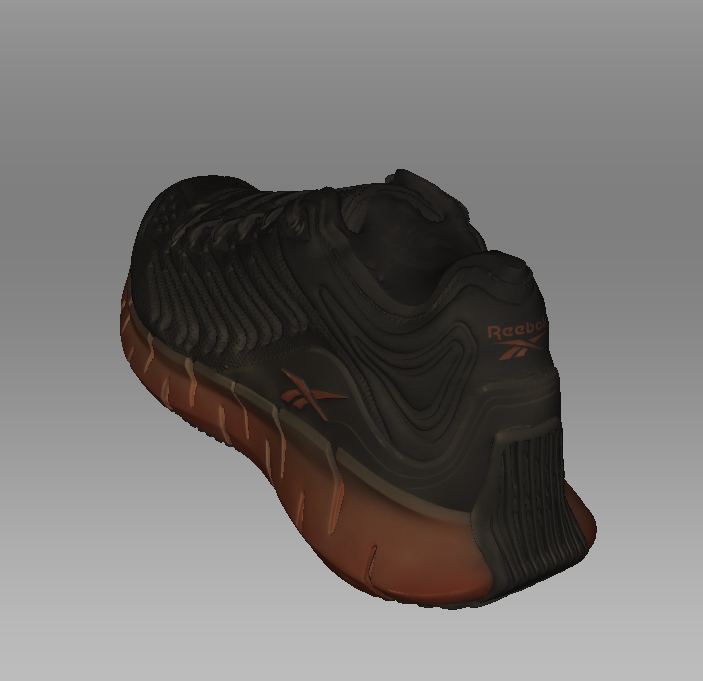

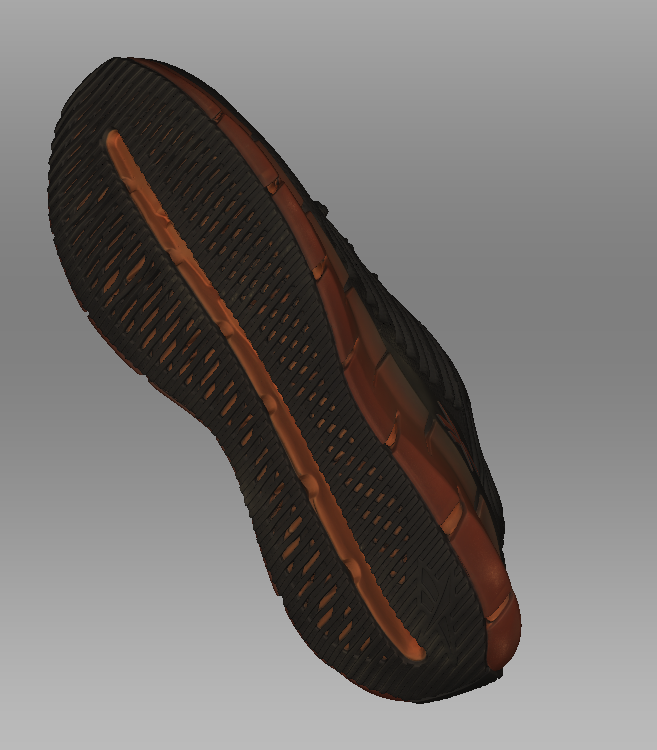

- Since access to the CAD file was not readily available in time for their campaign we needed to create a 3D file from scratch. So we whipped up the digital asset to kick off the project. 3D scanning took place within a couple of minutes of having full access to the physical shoe. Our team was able to utilize our in-house Artec Eva and render up a 3D CAD file within a few hours. You can see the scan images below to get a better understanding of the data captured.

- Geometry was created using several stitched together scans

Geometry was created using several stitched together scans

Using the Artec Eva we were able to capture a very details scan of the shoe.

- The texture was also captured during the initial scan output and processed using Artec Studio

Using the Artec Eva we were able to capture a very detailed scan of the shoe.

- Following scan capture, we ran a couple of test prints from the raw processed scan to see the quality of the original texture captured and its translation over to our new Mimaki 3D Printer. The results were pretty good but not quite perfect.

- This file was then brought into Zbrush where our team of digital sculptors cleaned up any imperfections in the geometry and added additional touchups to the model. Due to low light conditions during the scanning process, the vibrance of The Zig was not quite perfect. Our sculptors added additional saturation to the shoes’ orange hues, soles area, and logos to give that extra pop of colour.

- Our production team then reran the models on both the Mimaki 3duj-553 and the 3D Systems Project 660 to compare outputs and evaluate finishing options.

THE BOX

The second portion of the project consisted of a matching box to accommodate the pair of shoes. We produced a few variations in both traditional 2D and also 3D printing. Using the original box as a reference our sculpting team was able to replicate the design and graphics in zbrush for 3D production. You can see the final output below.