Figure 4 Rigid White

PRODUCTION RIGID

Opaque rigid white production-grade plastic for same-day parts. This biocompatible-capable material provides a smooth surface finish, long-term environmental stability, and long-lasting, clean white color.

PRODUCTION RIGID

Opaque rigid white production-grade plastic for same-day parts. This biocompatible-capable material provides a smooth surface finish, long-term environmental stability, and long-lasting, clean white color.

Figure 4® Rigid White is a production-grade opaque white material that provides long-term environmental stability and long-lasting, clean white color. This material is recommended for use in medical, consumer goods, and industrial manufacturing applications, and other applications where a smooth surface finish, long-term indoor and outdoor stability, and biocompatible capability are needed.

This resin exhibits thermoplastic behavior with necking at break, making it ideal for snap-fit applications. It also features 65°C heat deflection temperature and high elongation at break. Fast print speeds and simplified post-processing enable exceptional throughput.

The full suite of mechanical properties is given per ASTM and ISO standards where applicable. All parts are conditioned per ASTM recommended standards for a minimum of 40 hours at 23 °C, 50% RH. Material properties include physical and mechanical properties, as well as thermal, UL flammability, and electrical (dielectric strength, dielectric constant, dissipation factor, and volume resistivity).

Figure 4 technology prints parts that are isotropic in mechanical properties meaning the parts printed along either the XYZ axis will give similar results. Parts do not need to be oriented to get the highest mechanical properties, improving the degree of freedom for part orientation for mechanical properties.

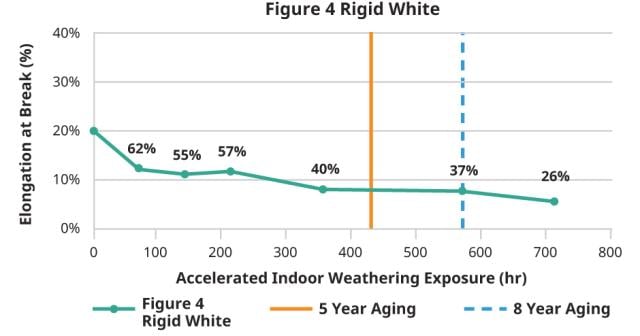

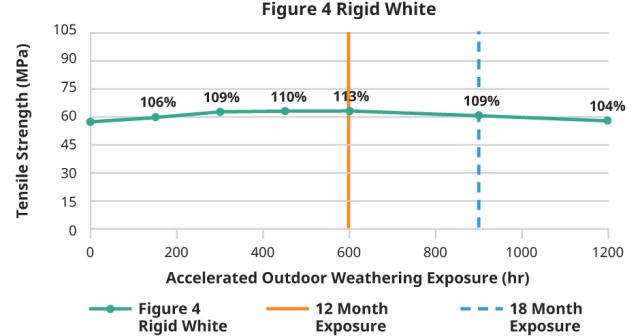

Figure 4 Rigid White is engineered to give long-term environmental UV and humidity stability and long-lasting clean white color. This material has been tested for its ability to retain a high percentage of its initial mechanical properties over a period of time. This test data provides real performance conditions to consider for the application or part.

The charts show a sampling of the dataset. The full data sheet includes indoor and outdoor stability data for tensile strength, elongation at break, tensile modulus, and impact strength. The actual data value is on the Y-axis, and data points are % of the initial value.

Tested per ASTM D4329 standard method.

Tested per ASTM G154 standard method.

Hydrocarbons and cleaning chemical compatibility can be critical to application compatibility. Figure 4 Rigid White parts were tested for sealed and surface contact compatibility per ASTM D543 test conditions and per USCAR2 test conditions. Notched impact strength is shown below. The full data sheet includes additional data tables for tensile strength, tensile modulus, and elongation at break.

2140 Dunwin Drive.,

Mississauga, Ontario L5L 1C7

Email: sales@objexunlimited.com

Phone: 416-233-7165

Mon – Fri

9am – 5pm EST