Our 3D Printing Processes

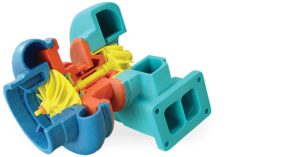

ColorJet Printing

Full-color concept models with quick production times. Whether printed with color or in standard white, parts can be additionally clear coated to add a hard, smooth coating or wax coated to smooth out the surface finish.

Multijet Printing

Need rapid prototypes of designs with smooth surfaces and high complexity?

Multijet printing is a great solution for high-resolution printing of small detailed and complex geometries.

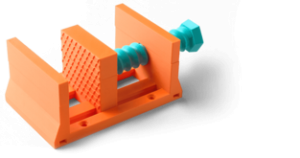

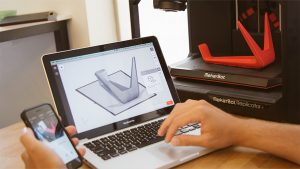

Fused Deposition Modeling

Fast and cost-effective process for proving designs, fit and function testing, small production runs, jigs, and fixtures. Allowing parts to be made direct from 3D CAD to thermoplastic materials without tooling.

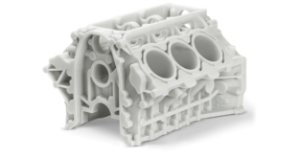

Stereolithography

Highest accuracy and smoothest surface finish of all 3D printed parts. Print highly detailed parts ranging from just a few mm in size, all the way up to 5 ft (1.5 m), with exceptional resolution and accuracy and virtually no part shrink or warping.

Selective Laser Sintering

Capable of producing highly durable and complex geometries for real-world testing while other additive manufacturing methods may become brittle over time. Ideal for snap fits and living hinges.

3D Printing Services

Concept Models

Whether you’re giving a presentation, showing off a new concept, or demonstrating a new product, we have the tools you need to build your model and get your message across.

Rapid Prototyping

With the latest printing technologies on-site and a wide range of materials to choose from, you can rest assured your prototypes will arrive on-time, with industry-leading results.

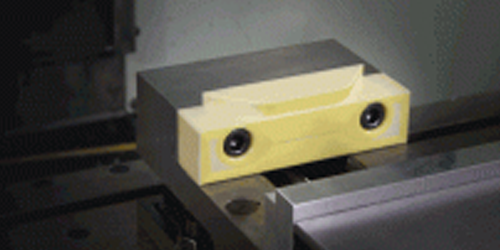

Direct Digital Manufacturing

Many of our customers choose additive as a method of production for their end-use products. Custom tooling, jig & fixtures can all be created using additive manufacturing to give your team a leap forward in your production schedule.

Jigs and Fixtures

Short Run Production

Print By Material

Many of our customers turn to material output and finish requirements when choosing the additive process right for them. Speak with one of our printing experts to see what material options are right for your application.

3D Scanning Services

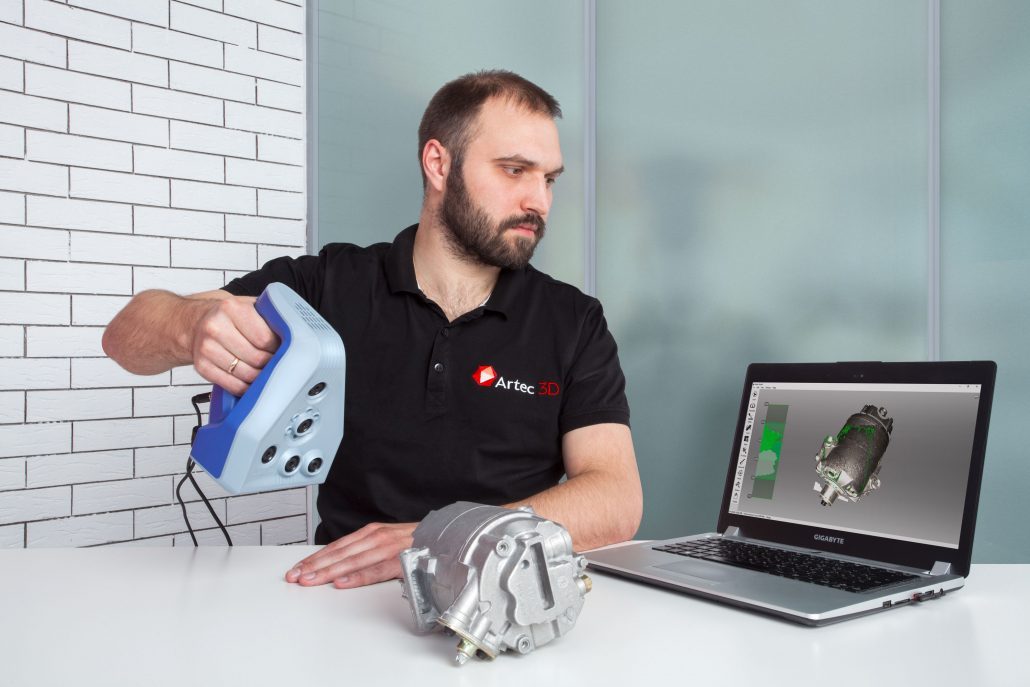

Handheld 3D Scanning

Our in-house Artec 3D Scanners deliver complex information about the shape of an object within a matter of seconds. Providing accurate, quick and detailed design data that can be used with objects of various sizes and degrees of complexity.

Scan to CAD

Turn your physical products, models jig, molds, fixtures, furniture and more into digital files that can than be used for a variety of applications with micron-level detail. Then import them into your favorite software for further render, analysis, inspection or development.

Heritage | Art | Forensics

For some of the most complex geometries such as art pieces, body scans, and character designs – nurb based software just doesn’t cut it. Digital sculpting and modeling is a vital part of bringing these ideas to life and our team has you covered.

Artist Capture

Clay & Artifact Preservation

Monument Capture & Archiving

Photogrammetry

Our proprietary photogrammetry solutions use multiple cameras to capture the object from different angles along with an algorithm that triangulates common points to analyze depth and create a 3D model. This technology gives our customers the best colour detail and texture outputs for people, animals, moving object that require instantaneous capture such as full body 3d scanning.

3D Design Services

Industrial Design

Are you looking to make your idea matter? With our on staff industrial design team, we are able to assist you through the process of design through prototyping for both simple and some of the most challenging product concepts.

3D CAD Design Services

Product Development

Concept Ideation

Design For Print

Do you have a great idea that you want to make a reality… but aren’t quite sure how? We have excellent clients drop by all the time that require an extra hand when taking their designs or models to the next level.

Direct Digital Design

CAD Design Validation

Print File Prep

Reverse Engineering

Creating 3D Models from scratch can be both time and cost-intensive. Reverse engineering using 3D scanning, you can complete a job in hours that normally takes days or weeks using traditional methods.

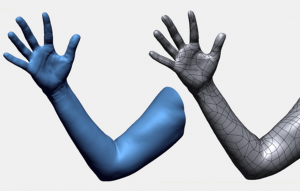

3D Modeling

For some of the most complex geometries such as art pieces, body scans, and character designs – nurb based software just doesn’t cut it. Digital sculpting and modeling is a vital part of bringing these ideas to life and our team has you covered.

Digital Sculpting

Texture Reprojection

Scan Retopology