[hs_action id=”5912″]

The ProJet® 7000 MP 3D Printer for high production in medical applications

The ProJet® 7000 MP stereolithography printer offers the industry’s first and most advanced 3D printing, ideal for medical applications with fine feature detail, accuracy and repeatability.

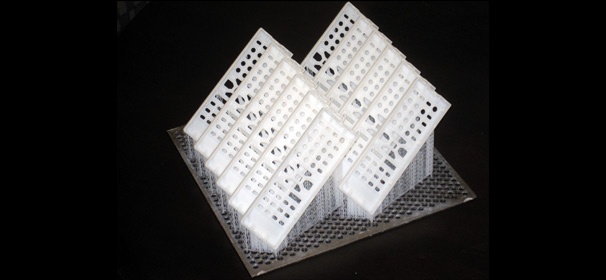

The ProJet 7000 offers a generous build size of 15 x 15 x 10 inches allowing rapid production of a large nuymber of medical parts, with a perfect finish. Bridges, crowns and orthopedic jaw models are almost immediately ready to be used in traditional production processes. Hearing aid shells are produced ready as custom-fit end-use parts.

With a range of materials and accuracy of 0.001-0.002 inches per inch of part dimension, the ProJet 7000 MP is perfect for your manufacturing needs.

Software supplied with this system enable the management of builds, queueing, part editing, stackign and nesting capabilities and build optimization.

Create your products perfectly and accurately with SLA 3D printing.

Deliver tailored treatments to your patients with precision and ease.

Work with a choice of build modes that range from high-definition to ultra high-definition to extra high-definition.

Mass manufacture using a generous build size.