Stereolithography

Great for concept models, rapid prototypes, master patterns, snap-fit assemblies, and form-and-fit testing.

Great for concept models, rapid prototypes, master patterns, snap-fit assemblies, and form-and-fit testing.

Stereolithography (SLA) models offer the most accurate type of fit/form prototype for the verification of any design before committing to your chosen production route. Its high accuracy and good surface finish makes it the preferred choice for designer models, engineering verification and master patterns for silicone rubber molds.

Stereolithography (SLA) utilizes a vat of liquid photopolymer resin cured by an Ultra Violet (UV) laser to solidify the pattern layer by layer to create a solid 3D model from customer supplied 3D data. The SLA process addresses the widest range of rapid manufacturing applications.

Tolerances for standard resolution:

Tolerances for high resolution:

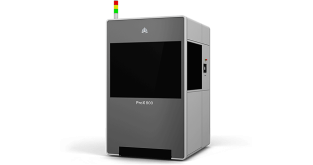

3D Systems’ SLA printers are able to print highly detailed parts ranging from just a few millimeters in size, all the way up to 1.5 meters (5 ft), with exceptional resolution and accuracy and virtually no part shrinkage or warping.

Prototypes, tools and production parts with the gold standard in 3D printing.

Highest 3D printed quality and accuracy for small to medium sized parts

Highest 3D printed part quality and accuracy, larger size

High 3D printing throughput, highest accuracy and detail

Extra large SLA 3D printed parts, highest throughput and accuracy

| Mechanical Properties | Tensile Strength | Tensile Modulus | Tensile Elongation at Break | Flexural Strength | Flexural Modulus | Hardness | Izod Impact -Notched | Heat Deflection Temp |

|---|---|---|---|---|---|---|---|---|

| Test Method | ASTM D638 | ASTM D638 | ASTM D638 | ASTM D790 | ASTM D790 | DIN 53505/2240 | ASTM D256 | ASTM D648 |

| Units | psi | psi | % | psi | psi | Shore D | (ft-lb)/in | °F |

| ABS-Like | ||||||||

| White (Std & High-Res) (Accura 55) |

9,200 – 9,850 | 360,000 – 390,000 | 5.3 – 15.0% | 10,400 – 11,200 | 320,000 – 340,000 | 86 | 0.31 – 0.51 | 120 – 127° |

| White (Renshape 7810) |

5,200-7,400 | 260,000-348,000 | 10 – 20% | 8,500-10,000 | 343,000 – 359,000 | 80 – 87 | 0.26 – 0.49 | 137° |

| White (Std& High-Res) (Accura 25) |

5,450 – 5,570 | 230,000 – 240,000 | 13 – 20% | 7,960 – 8,410 | 200,000 – 240,000 | 80 | 0.4 | 136 – 145° |

| Gray (Accura Xtreme) |

5,510 – 6,380 | 260,000 – 287,000 | 14 – 22% | 7,450 – 10,300 | 220,000 – 300,000 | 86 | 0.66 – 0.98 | 144° |

| Black (RenShape 7820) |

5,200 – 7,400 | 274,000 – 348,000 | 8 – 18% | 8,500 – 11,100 | 290,000 – 348,000 | 86 | 0.79 – 0.91 | 124° |

| High-Impact – White (Somos NeXt) |

5,900 – 6,300 | 343,000 – 361,000 | 8 – 10% | 9,800 – 10,300 | 350,000 – 366,000 | 82 | 0.88 – 0.97 | 131 – 134° |

| High-Impact – White (Accura Xtreme White 200) | 6,530 – 7,250 | 334,000 – 381,000 | 7 – 20% | 10,880 – 11,460 | 341,000 – 370,000 | 78-80 | 1.03-1.24 | 108° – 117° |

| High-Temp (Accura Bluestone) |

9,600 – 9,800 | 1,100,000 – 1,700,000 | 1.4 – 2.4% | 18,000 – 22,300 | 1,200,000 – 1,417,000 | 92 | 0.24 – 0.32 | 513 – 543° |

| White (VisiJet SL Flex) |

5500 | 235,000 | 16% | 8270 | 206,000 | 80 | 0.41 | 127° |

| Grey (VisiJet SL Tough) |

5950 | 274,000 | 18% | 8990 | 268,000 | 86 | 0.82 | 129° |

| Black (VisiJet SL Black) |

6500 | 312,000 | 5% | 1100 | 341,000 | 86 | 0.88 | 123° |

| Durable, PP-Like | ||||||||

| (Std& High-Res) (Accura 25) |

5,450 – 5,570 | 230,000 – 240,000 | 13 – 20% | 7,960 – 8,410 | 200,000 – 240,000 | 80 | 0.4 | 136 – 145° |

| White (VisiJet SL Flex) |

5500 | 235,000 | 16% | 8270 | 206,000 | 80 | 0.41 | 127° |

| Rigid, PC-Like | ||||||||

| (Std& High-Res) (Accura 60) |

8,410 – 9,860 | 390,000 – 450,000 | 5 – 13% | 12,620-14,650 | 392,000 – 435,000 | 86 | 0.3 – 0.5 | 127 – 131° |

| (Std& High-Res) (Accura ClearVue) |

6,700 – 7,700 | 329,000 – 383,000 | 3 – 15% | 10,400-12,200 | 287,000 – 335,000 | 80 | 0.7 – 1.1 | 124° |

| High-Temp (Std) (Accura PEAK) |

8,270 – 11,320 | 612,000 – 695,000 | 1.3- 2.5% | 11,170 – 18,380 | 606,000 – 695,000 | 86 | 0.4 – 0.5 | 172° |

| High-Temp (VisiJet SL Hi-Temp) |

9570 | 491,500 | 6% | 16250 | 446,500 | 86 | 0.48 | 134° – 230° |

| Clear (VisiJet SL Clear) |

7500 | 371,000 | 6% | 12,000 | 338,000 | 85 | 0.86 | 122° |

| Semi-Flexible, PE-Like | ||||||||

| PE-Like (VisiJet SL Flex) |

5500 | 235,000 | 16% | 8270 | 206,000 | 80 | 0.41 | 127° |

| Technician’s Choice | ||||||||

SLA® Production Printers build accurate parts directly from 3D CAD data without tooling by converting liquid materials and composites into solid cross-sections, layer by layer, using an ultraviolet laser. The bed then lowers, the part is coated with a new layer of resin, and the next layer is built on top of the others until the part is finished. When a part is complete, it is cleaned in a solvent solution to remove wet resin remaining on the part surface. Afterward, the part is put in a UV oven to complete the curing process. SLA® Production Printers offer high throughput, build size up to 1524 mm, unmatched part resolution and accuracy, and a wide range of print materials. No process addresses a wider range of applications, including the most demanding rapid manufacturing applications.

When Charles ‘Chuck’ Hull, the founder of 3D Systems, invented Stereolithography, SLA, in 1986, he launched a revolution in product development across every marketplace from transportation, recreation and healthcare to consumer goods and education. Through continued innovation we extend our technology leadership, offering customers new and improved Production Printers and Print Materials and expanding our patent portfolio.

(View the video to the left to see how SLA 3D printing works.)

SLA is all about precision and accuracy, so it is often used where form, fit and assembly are critical. The tolerances on an SLA part are typically less than .05mm, and it offers the smoothest surface finish of any additive manufacturing process. Considering the level of quality SLA can achieve, it’s particularly useful for creating highly precise casting patterns (e.g., for injection molding, casting and vacuum casting) as well as functional prototypes, presentation models, and for performing form and fit testing. SLA technology is extremely versatile and it can be used in any number of areas that require precision above all else.

Keep in mind that, unlike with SLS, SLA parts do utilize support structures, and they require a bit more post-processing. But the post-processing options are also some of SLAs greatest advantages. Models can be vapor honed, or bead or sand blasted. SLA parts can even be electroplated with metal, such as nickel. Electroplating not only makes the part significantly stronger, but it also makes the part electrically conductive and more dimensionally stable in moist environments.

In terms of benefits, SLA allows us to save time on highly precise parts, especially when you require a number of functional prototypes or a quick single casting pattern. SLA brings us painstaking accuracy without the painstaking time. Because of SLA’s speed and precision, prototypes are easy to make and faithful to the final design, which means we can identify design flaws, collisions and potential mass-manufacturing hurdles before production begins. For low- to mid-volume parts normally machined from polypropylene or ABS, SLA provides comparable characteristics and doesn’t require slow, expensive retooling for customization or in the event a tooling change is required. In addition, SLA allows for lower material costs, as the unused resin stays in the vat for future projects.

SLA materials are wide ranging in mechanical properties and offer wide application opportunities for parts requiring ABS or polypropylene-like characteristics such as snap-fit assemblies, automotive styling components and master patterns. SLA materials are available for higher-temperature applications and clear materials are available with polycarbonate-like properties. Biocompatible materials are available for a wide range of medical applications such as surgical tools, dental appliances and hearing aids. Other materials are specifically formulated for patterns, offering low ash creation and high accuracy while also being expendable.

Stereolithography (SLA) is often considered the pioneer of the additive manufacturing processes, with the first production systems introduced in 1988 and patented by 3D systems founder Charles (Chuck) W. Hull. The SLA process utilizes a vat of liquid photopolymer resin cured by ultraviolet laser to solidify the pattern layer by layer to create or “print” a solid 3D model.

The SLA process utilizes a vat of liquid photopolymer resin cured by ultraviolet laser to solidify the pattern layer by layer to create or “print” a solid 3D model.

An Ultra Violet (UV) laser beam is directed by a computer guided mirror onto the surface of the UV photopolymer resin. The model is built one layer at a time from supplied 3D CAD data.

The laser beam traces the boundaries and fills in a two-dimensional cross section of the model, solidifying the resin wherever it touches. Each successive layer is applied by submersion of the build platform into the resin as the part gradually develops and the platform descends into the liquid resin.

Once the model is complete, the platform rises out of the vat and the excess resin is drained. The model is then removed from the platform, washed of excess resin, and then placed in a UV oven for a final curing. After curing SLA parts are then ready for post processing as required by the specific application.

Tooling and Patterns:

• Investment Casting Patterns

• Jigs and Fixtures

• Cast Urethane Master Patterns

Custom industry applications such as healthcare with biocompatible materials for surgical tools, dental appliances, hearing aids.

Frequently, parts produced by SLA are used as master patterns (pattern transfer process). The pattern is transferred to urethane castings using silicone rubber molds (SRM) or utilized for metal investment casting.

Rapid Prototypes:

• Design Appearance Models

• Proof of Concept Prototypes

• Design Evaluation Models (Form & Fit)

• Engineering Proving Models (Design Verification)

• Wind-Tunnel Test Models

Tooling and Patterns:

• Investment Casting Patterns

• Jigs and Fixtures

• Smooth surface finish

• High precision

• Short lead times

• Wide variety of material and post processing options

You’ve seen it: The bobblehead that could only be identified as the star athlete by the name or number on his or her uniform. Or the doll that fails to capture an actress’ fine…

In February 2014, the team at American Precision Prototyping (APP) was presented with a unique challenge: redesign, prototype, cast, decorate and ship 150 cast ure

There’s a moment that every industrial designer dreads: When his or her ideal design bumps up against manufacturing reality. Confederate Motors has faced that moment many times in…

2140 Dunwin Drive.,

Mississauga, Ontario L5L 1C7

Email: sales@objexunlimited.com

Phone: 416-233-7165

Mon – Fri

9am – 5pm EST