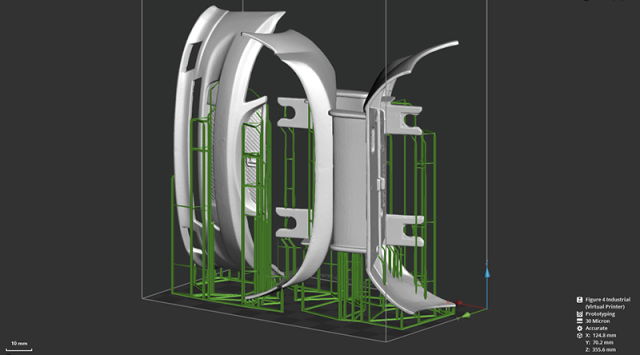

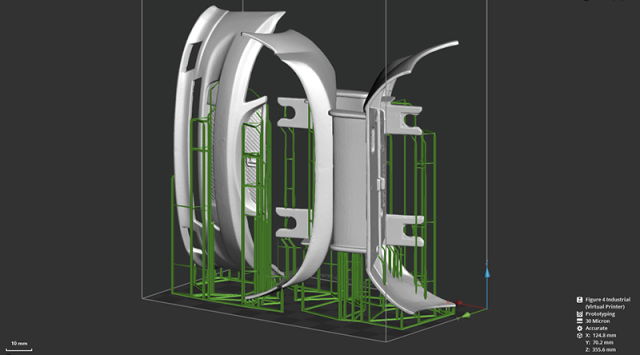

Figure 4

MAKING 3D PRODUCTION REAL WITH SCALABLE, MODULAR FACTORY SOLUTIONS

The industry’s first scalable, fully-integrated 3D printing platform with ultra-fast speed enabling throughput improvement up to 15x and up to 20% lower parts cost.*

MAKING 3D PRODUCTION REAL WITH SCALABLE, MODULAR FACTORY SOLUTIONS

The industry’s first scalable, fully-integrated 3D printing platform with ultra-fast speed enabling throughput improvement up to 15x and up to 20% lower parts cost.*

PRODUCTIVE AND COST-EFFECTIVE DIGITAL MOLDING SOLUTIONS FOR ANY PRODUCTION ENVIRONMENT

There is a Figure 4 solution to match any production requirements:

Industry’s first scalable, fully-integrated factory solution for direct 3D production

3D Systems Figure 4 makes 3D production a reality—with increased productivity, durability, repeatability and lower total cost of operations (TCO). Figure 4 delivers productivity enabled through speed and automation with real world repeatable, accurate parts with demonstrated Six Sigma performance in a diverse range of robust, production-grade materials.

Figure 4™ delivers ultra-fast additive manufacturing technology in discrete modules, allowing it to be placed into automated assembly lines and integrated with secondary processes, including the washing, drying and curing of end-use parts. Digital molding reduces development costs, increases productivity by eliminating the cost and time of expensive tooling. The digital molding workflow process speeds and simplifies production with automation of low volume plastic parts production. Figure 4 delivers repeatable, true-to-CAD part accuracy in an agile, in-line manufacturing workflow.

Delivered in configurable units for anytime scalability, Figure 4 allows manufacturing capacity to grow alongside demand – from a standalone printer for rapid prototyping and low volume direct 3D production, to modular systems that grow as your volume grows, up to a fully-automated, fully-integrated factory solution.

3D Systems’ Material Design Center has over 30 years of proven R&D experience and process development expertise. The production-grade materials available for Figure 4 include a broad and expanding range of materials to enable true replacement of traditional molding and urethane casting.

Figure 4 solutions use 3D Sprint, 3D Systems’ advanced software for file preparation, editing, printing and management from a single, intuitive interface. 3D Sprint enables the customer to significantly decrease cost of ownership of their 3D printers by reducing the need for costly software seats by third party vendors. 3D Sprint automatically generates exceptionally efficient supports requiring far less material, which can lead to significant savings.

2140 Dunwin Drive.,

Mississauga, Ontario L5L 1C7

Email: sales@objexunlimited.com

Phone: 416-233-7165

Mon – Fri

9am – 5pm EST