Choosing the Right 3D Scanner for your application

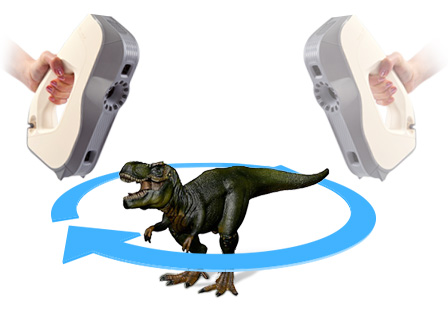

For most people, purchasing a 3D scanner is a new experience. This process is complex and confusing since each 3D scanning system has its own features and uses different technologies (e.g. laser, white-light, and blue diode). 3D scanning is a technology that can help you accomplish a task faster and more efficiently. Which scanner configuration is best suited for your particular application really depends on your needs. Therefore, the first step is to define what you want to achieve. Otherwise you will have no method to evaluate whether the 3D scanners you are considering will meet those requirements.

Here are some key questions you need to answer to help you

1. What are you trying to scan?

Defining what you want to scan will determine what features are important when evaluating 3D scanners. For example, a 3D scanner that is great at scanning human faces might not be good for scanning buildings. The more specific you are at defining what you want to scan, the easier it will be to find a suitable scanner for your application.

2. What is the size of the target object?

Most 3D scanners are optimized for a particular scanning window or object size. Typically, you would need to use different scanners to scan objects of different sizes. For example, you would use a different 3D scanner for scanning a small object as opposed to a large object. Most 3D scanners are optimized to scan objects from approximately a few inches to two feet. The further you go from this standard size, the higher the price the scanner will likely be.

3. How much accuracy do you need?

Accuracy is the quality of being close to the true value of the object. It is usually defined as Z or depth accuracy on the specification sheet. This question is critical because accuracy will have a significant impact on the price of the scanner. High accuracy is appealing to everyone although it is the single largest factor influencing cost.

4. How much resolution do you need?

Resolution measures the amount of detail you want to acquire from the object you are scanning. Like accuracy, the amount of resolution you need, will have a direct effect on the price of the 3D scanner. Higher resolution scanners that capture more detail will cost more.

5. How fast do you need to scan?

For scanning of static objects, the scan time is usually not as significant as moving objects. A single scan that takes under a minute is acceptable for most people. For the scanning of people, the faster the better because it is difficult to stand still for long periods of time. A scan speed of 1.5 seconds or less would be best. You need to consider that processing the resulting scan data also takes time, and faster processing speed is generally associated with higher cost.

6. What do you plan to do with the data ?

For most projects, 3D scanning is the first part of the project. Scan data is ultimately used for other purposes, whether it is 3D printing, visualization or inspection. The downstream data path is different for various applications. This helps to determine the features you need in a scanner and what other data processing software you will need to complement the scanner. Once you have your 3D data, there is data cleanup and data conversion tasks that need to be done in other software packages.

7. What is your scanning environment?

Every 3D scanning system has an ideal scanning environment. Most 3D scanners work well in an office lighting environment. All other environments add additional challenges to the equation. If you want to scan outdoors or in a moving vehicle, a greater level of complexity will be added to the project. If you are able to scan in a normal scanning environment you should be able to purchase less expensive equipment than if special conditions are needed.

8. What is your budget?

Ultimately, there is no point in finding out that you need a $50,000 scanner with a $5,000 budget. Sometimes you need to trade off some features in order to fit your budget and find a way to “make do” with less features. Remember to prioritize the features that will make your job less difficult.

9. Who will be operating the scanner?

It is easy to forget that 3D scanning is a complicated task that requires training. Give a top of the line digital camera to a novice will result in poor pictures. However, give the same equipment to a professional and you will get award winning results. The same applies to 3D scanning equipment. If the operator has no previous training in 3D scanning it doesn’t matter how much the equipment costs the results will be poor. You need to invest time learning the system that will reward you with good scan results.

For more information, please contact us, call or email:

Tel: 416 233-7165

Email: sales@objexunlimited.com

Website: www.objexunlimited.com