[hs_action id=”5212″]

Metal 3D printing for industrial applications

3D Systems brings its legendary reliability and repeatability to production-level Direct Metal Sintering (DMS) with the ProX™ 300 3D printer.

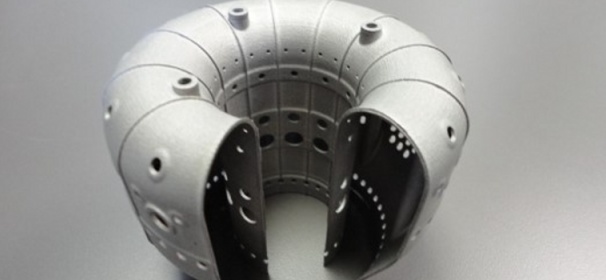

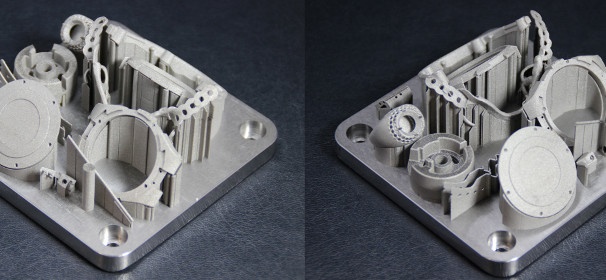

The ProX 300 3D printer makes additive manufacturing an industrial option for the production of metal parts. The ProX 300 is the largest in our DMS range, offering a build volume of 9.8 x 9.8 x 11.8 in (250 x 250 x 300 mm). It features an automated material loading and recycling system, and supports materials including Maraging 1.2709, Stainless 17-4PH, Ti6Al4V, AlSi12.

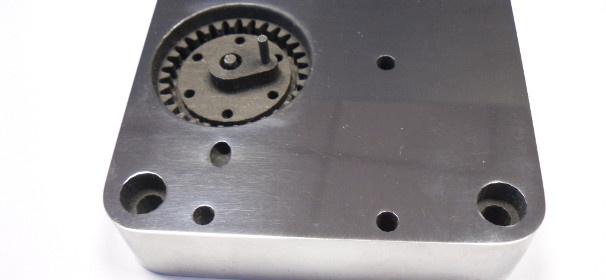

The ProX 300 is a high-performance, high-quality alternative to traditional manufacturing processes, offering reduced waste, greater speeds for production, short set up times, very dense parts, and the ability to produce very complex assemblies as a single parts.

About ProX DMS 3D Printers

All 3D Systems’ DMS printers create chemically pure, fully dense metal and ceramic parts, and they deliver accuracy compatible with EN ISO 2768 (fine) machining tolerances and a repeatability of about 20 microns in all three axes. Materials include stainless steel, tool steel, super alloys, non-ferrous alloys, precious metals and alumina. The outstanding output quality, with high accuracy, finish, reliability and repeatability, and a choice of more than 15 materials, makes these industry-leading machines highly attractive to manufacturers.

The ProX line of DMS 3D printers are providing seamless and intuitive metal 3D printing in a variety of industries: custom dental prostheses, orthopedic implants, tire molds, watch manufacturing, aerospace parts and more. In addition, these systems are wisely used for direct creation of conformal tooling, tooling insert and blow mold production.

Robust manufacturing floor platform

Patented powder layering system guarantees outstanding quality

Exceptional surface finish and resolution

Excellent accuracy and repeatability

Fully dense parts with superior mechanical properties

Fast build speeds