3D scanning is evolving at an incredible pace, and if you haven’t explored the latest updates in Artec Studio 19, you’re missing out! In a recent webinar, Steve Cory, President of Objex Unlimited (Canadian Artec Reseller), broke down the game-changing features of the software and the powerhouse lineup of Artec scanners.

Key Takeaways from the Webinar

Scan Decimation & Improved Performance

We’ve all dealt with massive 100GB+ scans that are nearly impossible to open. Artec Studio 19 solves this with scan decimation, freeing up RAM and making processing a breeze. The new version also enhances surfacing, CAD output, and measurement tools—everything is faster and better.

Notably, mesh simplification is now 10x faster, and OBJ exports that once took 5-10 minutes now happen in seconds. The updates keep coming, making the software more powerful and user-friendly.

Scanner Agnostic & Perfect for Education

A standout feature of Artec Studio 19 is that you don’t need an Artec scanner to use it! This opens up incredible possibilities, especially in education. Students can now use a simple phone camera to generate decent scans, making 3D scanning more accessible than ever before.

Artec’s Lineup of Industry-Leading Scanners

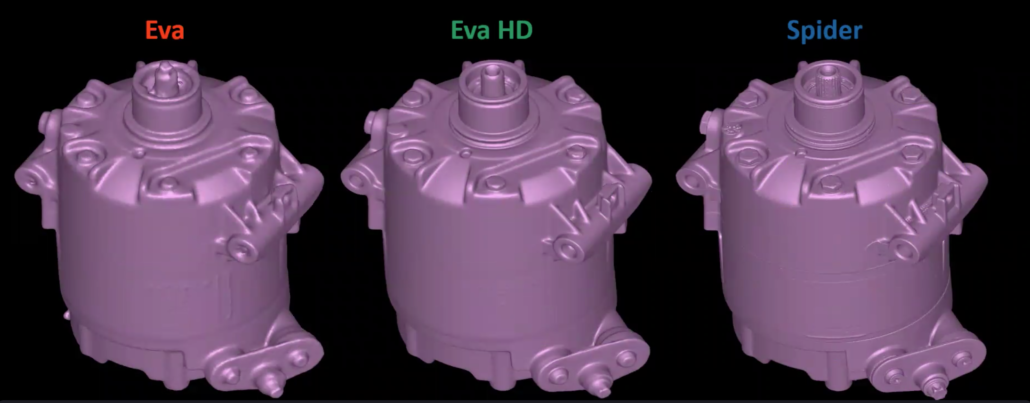

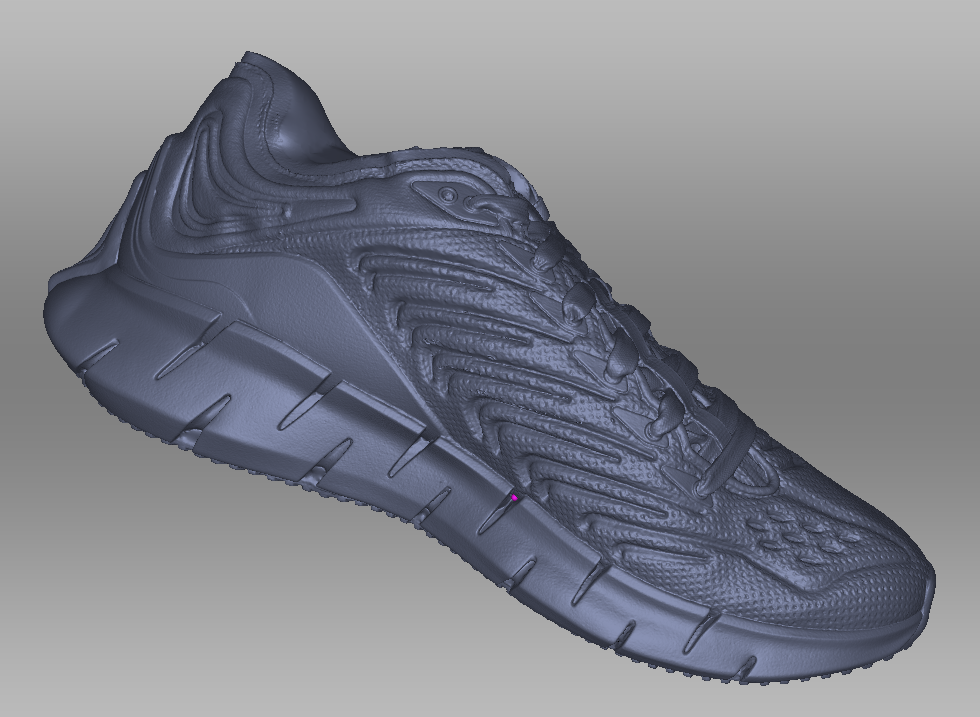

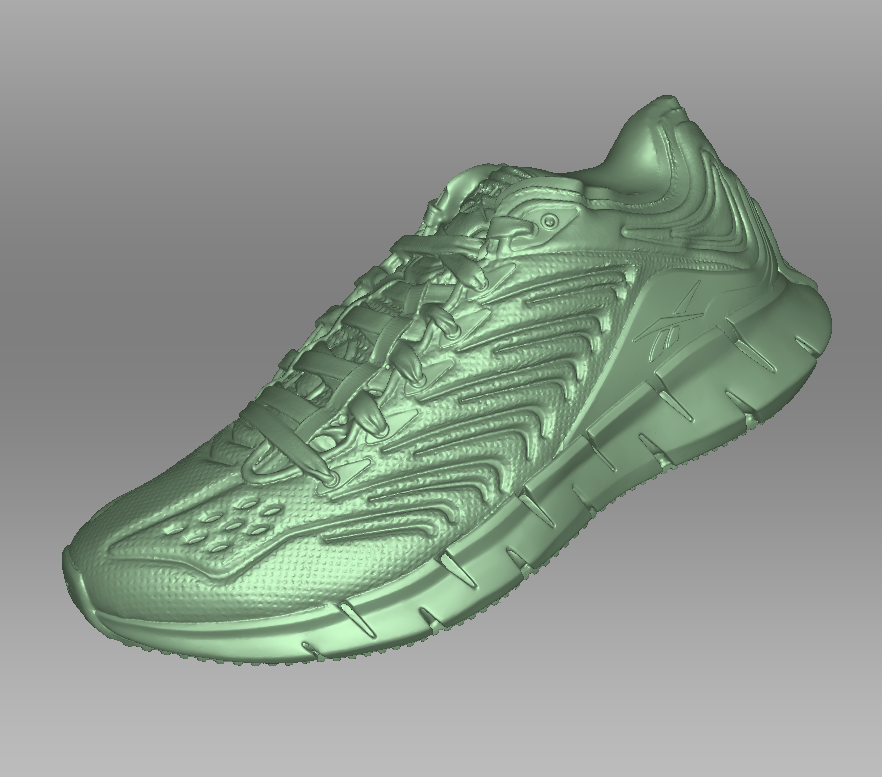

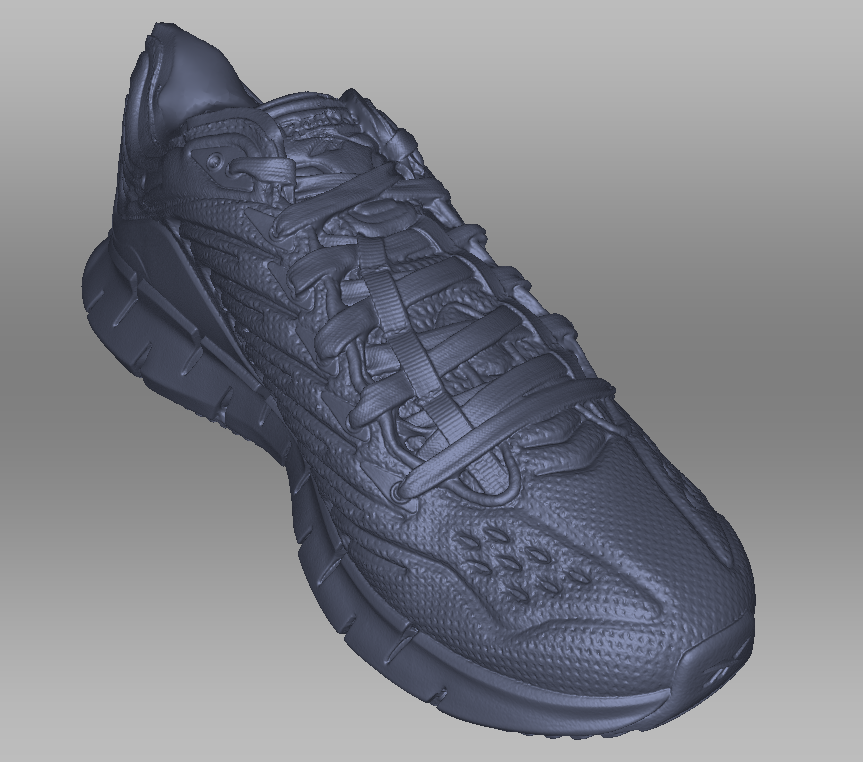

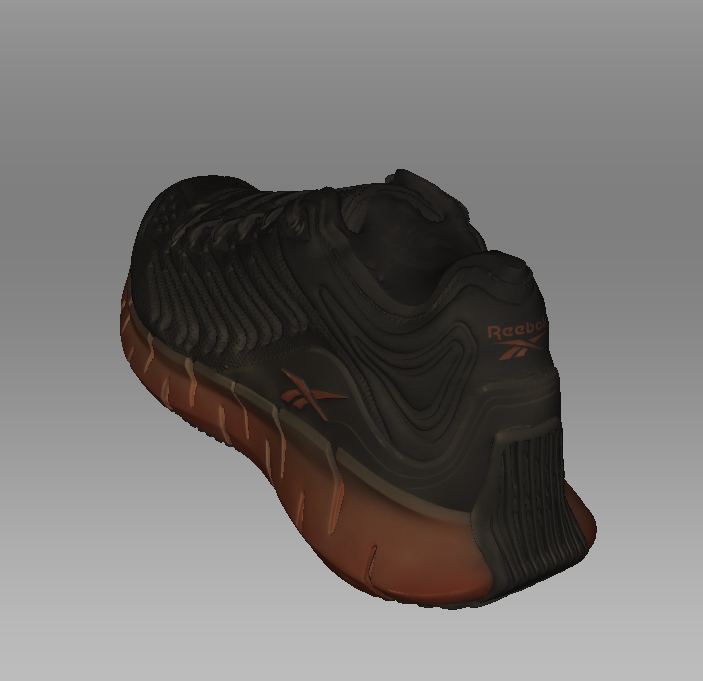

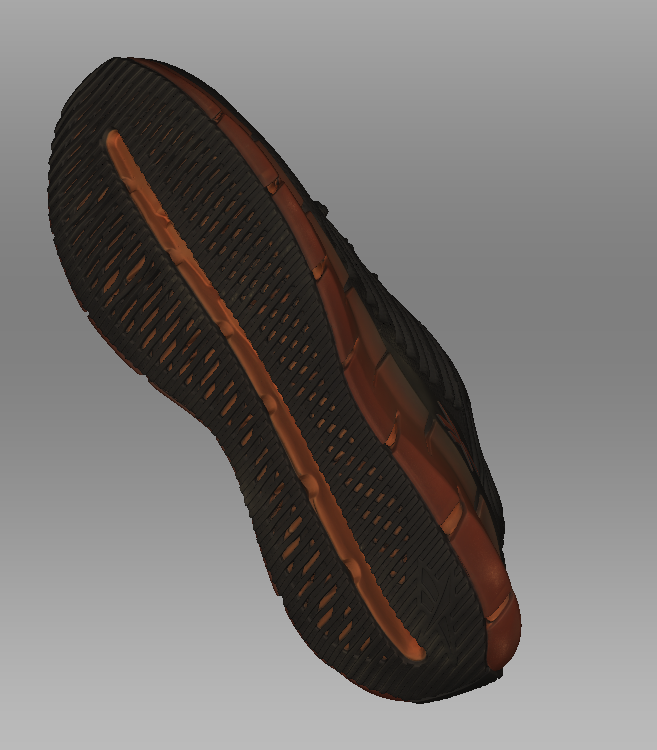

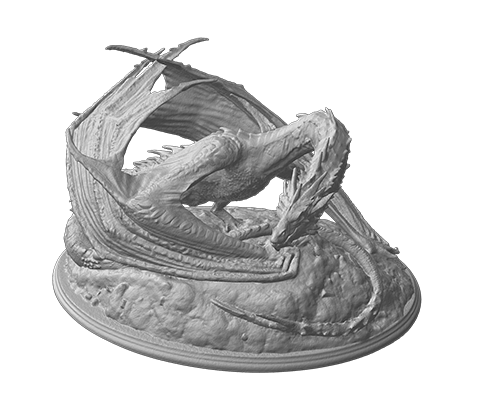

Steve also walked through the diverse Artec scanner lineup, showcasing how each tool fits specific use cases:

🔹 Artec Leo – Wireless, perfect for large objects (1-10m). Portable and rugged—ideal for fieldwork.

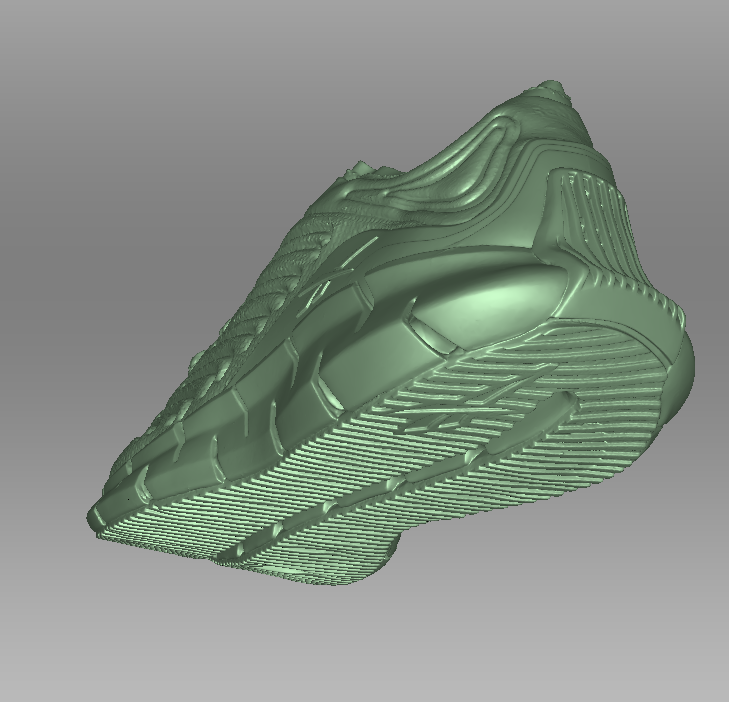

🔹 Artec Spider 2 – Superior accuracy for small objects with sharp detail.

🔹 Artec Eva & Eva Lite – Affordable, reliable workhorses with wired operation.

🔹 Artec Micro 2 – Designed for ultra-precise small object scanning with photogrammetry.

🔹 Artec Ray 2 – LiDAR scanning for large environments, from warehouses to landscapes.

🔹 Artec Point – The highest accuracy scanner (2 microns), perfect for detailed industrial applications.

Pro Tips for Better Scanning & Workflow

Steve shared valuable insights on optimizing scan projects:

- Break large scans into sub-100GB files to manage RAM efficiently.

- Use high-definition rebuild settings strategically.

- For mixed-detail projects, combine Leo for large areas and Spider for intricate details.

Why Objex Unlimited Doesn’t Rent Scanners

Many ask about renting scanners, but Objex Unlimited sticks to professional scanning services. Why? Scanning isn’t just about hardware—it’s about expertise. Their trained technicians ensure high-quality results, eliminating costly beginner mistakes.

Try It Yourself!

Interested in seeing these tools in action? Visit Objex Unlimited’s Mississauga facility for a hands-on demo, or check out their website for more details.

Final Thoughts

Artec Studio 19 and Artec’s scanners are reshaping the 3D scanning landscape. Whether you’re in manufacturing, education, or art restoration, these tools streamline workflows and unlock new possibilities. Ready to step up your 3D scanning game? Get in touch with Objex Unlimited today!