As Canada’s only 3D reseller running the Mimaki 3DUJ-553 equipment in-house, Objex Unlimited, is excited for the announcement of the new full-color (colour) Mimaki 3DUJ-2207 UV Inkjet 3D Printer. Extremely thrilled with the quality of parts being produced on our larger format 3DUJ-553, Mimaki’s lineup now comprises of the 3DUJ-2207, and 3DGD-1800 3D printers. Read the full press release below:

Source: https://www.mimakieurope.com/

- The new Mimaki 3DUJ-2207 3D Inkjet Printer boasts full-colour high definition production in a sleek, compact design, with over 10 million colours

- The machine delivers an affordable, scalable solution to drive accessibility to 3D printing and deliver its cutting-edge technologies to a host of new customers

Mimaki Europe, in conjunction with Mimaki USA, a leading manufacturer of inkjet printers and cutting systems, today announces the launch of its new compact, full-colour 3DUJ-2207 UV Inkjet 3D Printer. Previously the first to bring over 10 million colours to the 3D printing market with its larger-scale industrial counterpart, the 3DUJ-553, Mimaki now combines the same impressive colour range and renowned build quality in a compact, affordable solution. With this latest offering, Mimaki aims to extend the reach and accessibility of its cutting-edge 3D printing technologies to an entirely new segment of customers.

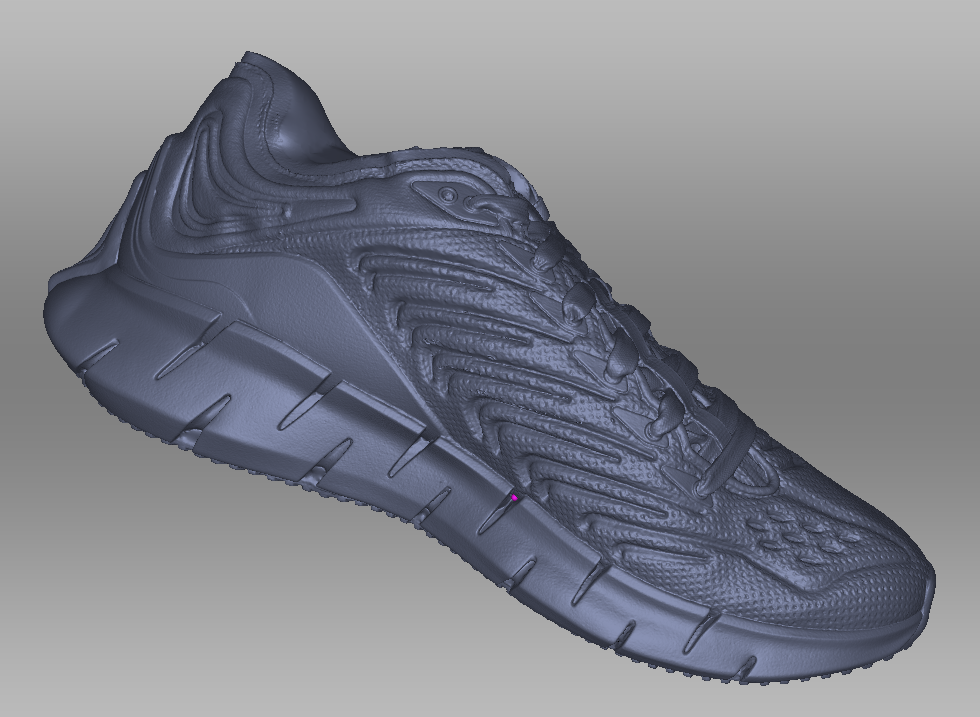

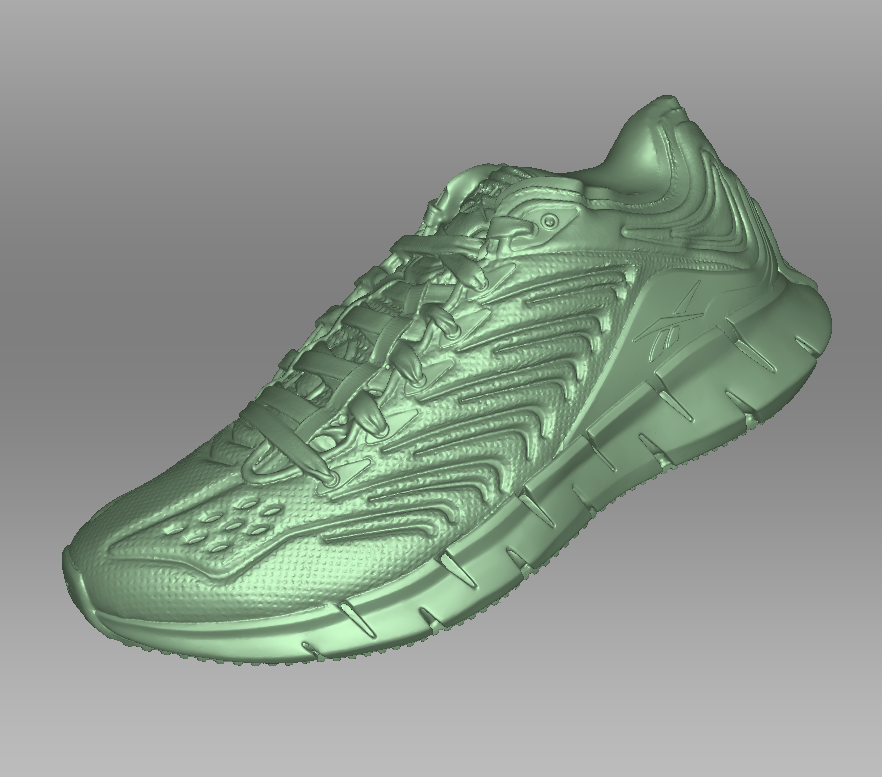

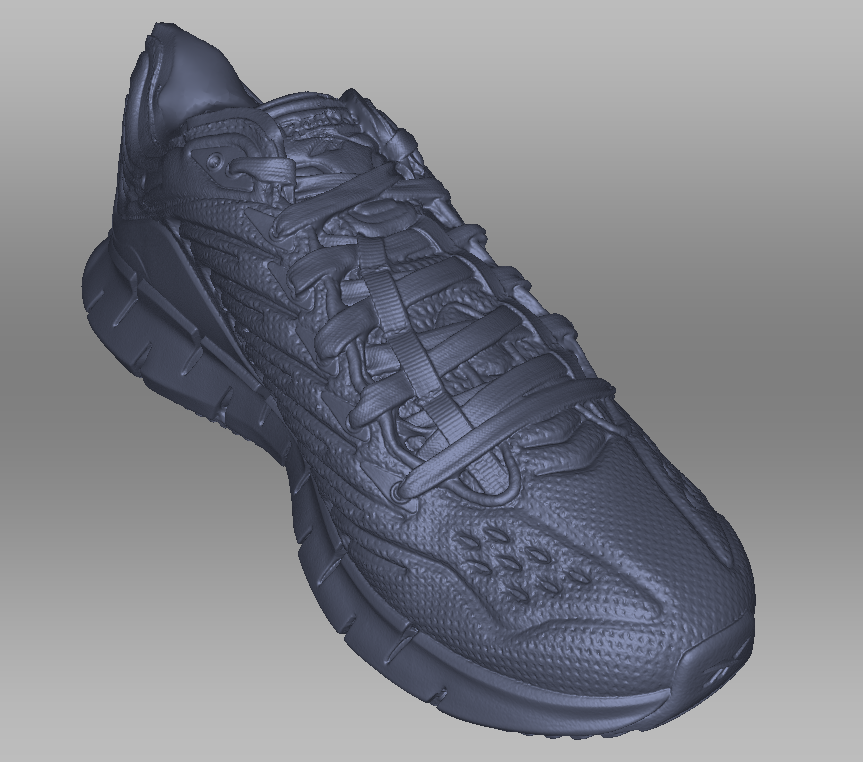

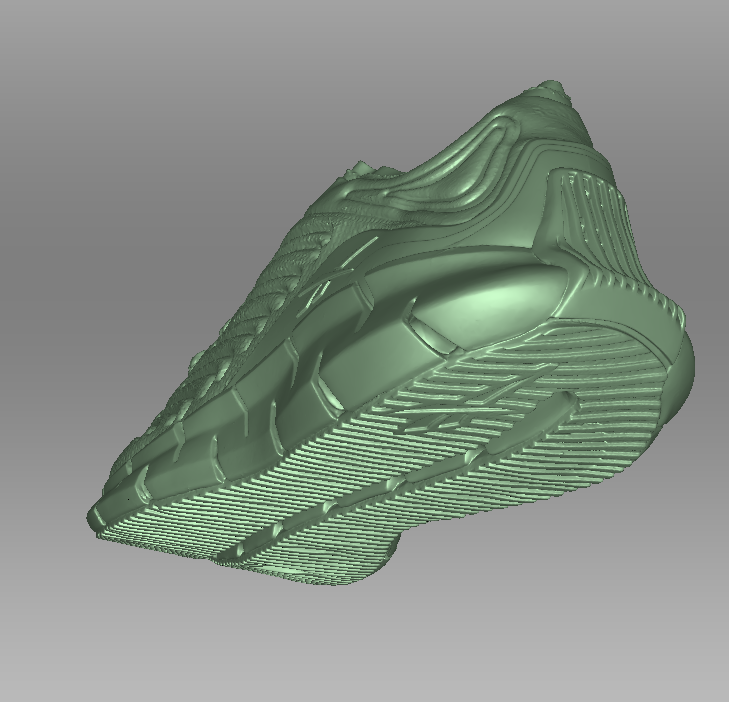

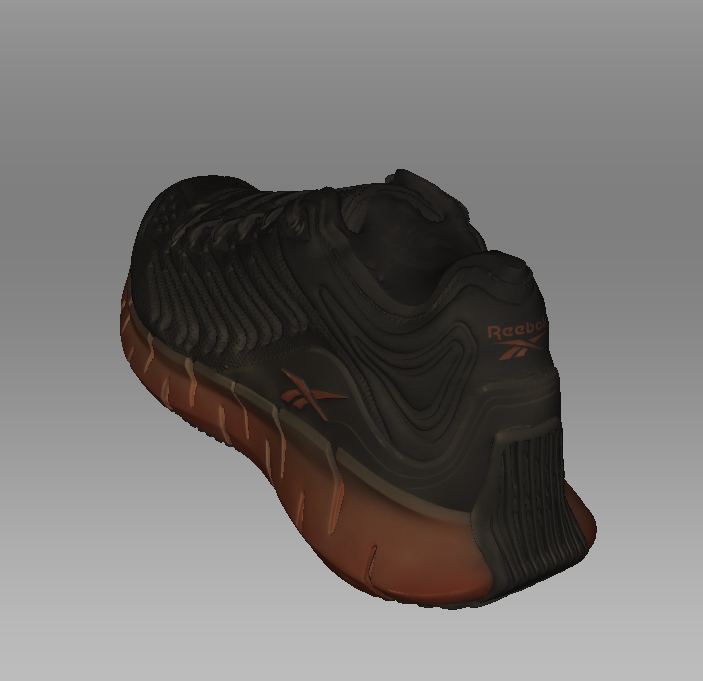

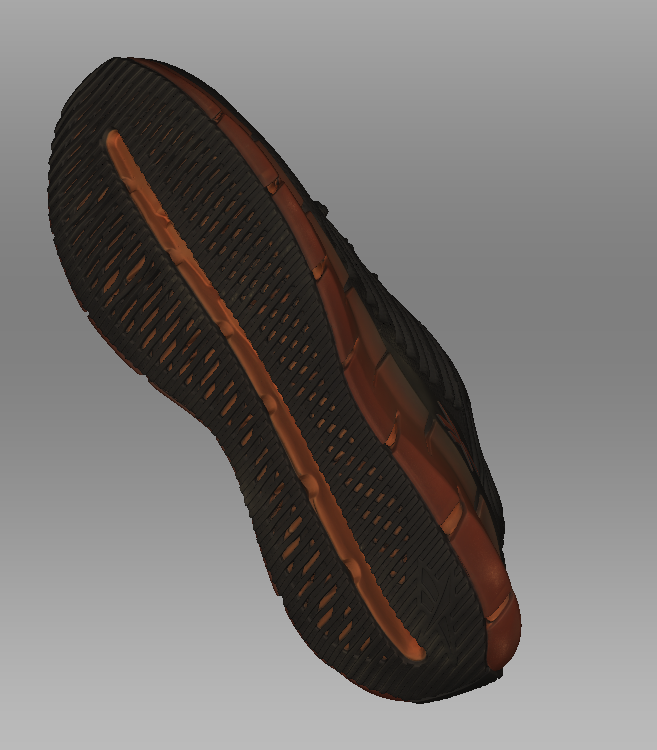

The innovative 3D printing solution represents a huge step forward for detailing and post-processing, with the unique combination of its full-colour capabilities and water-soluble support materials enabling super-fine details to be printed in vibrant colour, and then beautifully preserved without the substantial breakage risks usually associated with manual cleaning, painting and finishing. With additional features such as Mimaki’s trademark clear resin, which can be utilized alone or mixed with colours to achieve varying levels of transparency, the new 3DUJ-2207 3D printer presents a robust, advanced 3D printing solution with an affordable price tag – all within a machine sufficiently compact to fit in an office elevator.

“Here at Mimaki, we do not stop at developing disruptive technologies – we make it our business to look even further beyond this, continually striving to find ways in which we can then accelerate the adoption of these technologies and drive the wider industry forward,” comments Danna Drion, Senior Marketing Manager at Mimaki Europe. “Our new 3DUJ-2207 3D Printer is a prime example of this. We had already raised the bar in 3D printing by delivering the world’s first 3D printer with over 10 million colours – but now, with the introduction of our new 3DUJ-2207 3D Printer, we are bringing these 10 million colours to a host of new customers, which in turn means new applications and an even quicker uptake of 3D printing technologies as a whole.”

Set to be commercially available worldwide [Canada] from January 2021, the 3DUJ-2207 has been designed with functionality at its core, with the compact design and reduced 203 x 203 x 76mm build space just two of many key features which demonstrate its unique versatility and make it ideally suited for office environments. The 3D printer’s quiet performance and optional deodoriser minimize some of the primary disruptions usually associated with 3D printing technologies, ensuring maximum workability in busy workspaces.

Utilizing UV-curing inkjet technology, the expansive high-definition colour expression made possible with the Mimaki 3DUJ-2207 3D Printer is around twice that of powder bed manufacturing methods. This provides new possibilities for prototyping and enables the accurate reproduction of subtle colour differences which are critical for many industrial design applications such as medical and architectural modelling. Additional applications include small-scale models for design offices and educational settings, as well as collectible figures.

Drion concludes, “By combining our technological expertise with a wealth of industry experience and market insight, we have been able to create an innovative, inspired solution that merges functionality, affordability and design in a way that really will be game-changing for a lot of creators. This launch will deliver a world of new possibilities to designers and product developers, for many of whom the idea of high-definition full-colour 3D printing might previously have been out of reach, and that is something we are extremely proud of.”

The Mimaki 3DUJ-2207 3D Printer will be exhibited online at Formnext Connect and as part of Mimaki’s latest virtual event, the Mimaki 3D Experience, from 10th November to 16th December.